A lot of businesses benchmark themselves against other companies in the same industry and against themselves over time using various metrics and key performance indicators (KPI’s). One example of this is Solomon Associates Benchmarking which is widely used, especially in the refining and petrochemicals industry. This benchmarking process is often used to identify your competitive position, optimize plans or set performance targets.

Using this type of benchmarking process, it is possible to illustrate the operational benefits of being a top 25% performing company as oppose to being a bottom 25% performing company. A top 25% (we call this top quartile in Emerson) performing company generally has greater plant uptime, reduced operating costs, more productive people and operates more safely and without any environmental compliance problems.

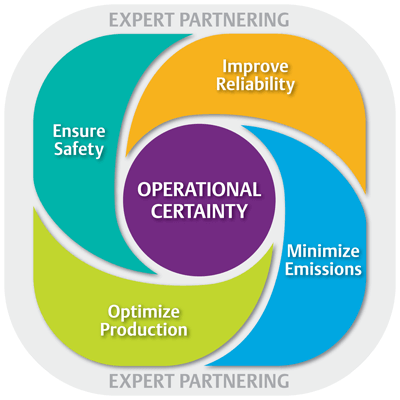

At Emerson, we have a wide portfolio of products and services which can be used by our customers in the process industries to help them become a top quartile company. Our Operational Certainty Framework is a consulting methodology to help our customers identify what challenges are preventing top quartile performance and to define an automation strategy which will address those challenges – maximizing shareholder value by reducing operating expenditure and improving plant availability.

We define Operational Certainty in terms of impact and expertise domains, recognizing that these domains are inter-dependent. For example improving reliability will also improve health and safety.

We define Operational Certainty in terms of impact and expertise domains, recognizing that these domains are inter-dependent. For example improving reliability will also improve health and safety.

Most industrial accidents happen when a plant is transitioning from one operating state to another such as start-up or shutdown. The domains which our Operational Certainty consultants refer to are illustrated in the figure below. These domains are applicable to all process industries.

Due to the inter-dependency of the domains, we recommend that the Operational Certainty engagements cover all domains initially. If you are already actively addressing different domains through your automation strategy, and you are particularly concerned about one underperforming domain, we are of course happy to focus on the domain of concern. Indeed, the initial consultancy investigations may themselves identify the need to focus on a particular domain.

Which type of Operational Certainty Engagement is right for me?

There are a number of considerations when deciding on the type of Operational Certainty Engagement to pursue with Emerson. There are two basic questions that you need to address: what’s the scope of the engagement going to be, and what’s the best engagement methodology to follow? The first scope consideration is often at which level in the organisation to target for greatest impact. Emerson has experience facilitating at plant, site and the corporate levels.

If, as a business, you are centralizing automation functions then the corporate level may be the best approach. If each site is relatively autonomous, with little corporate direction, then the site level may be more prudent. Particularly if it is one site which is under-performing. You also need to think about whether you want to focus on a single impact/expertise domain, or you want to take a holistic view of performance and consider the full Operational Certainty Framework (this will always identify far more improvement opportunity, but may not fit with your immediate priorities and focus).

The second consideration is the type of engagement. Emerson generally recommends that a traditional consultancy study be performed first to gather data and assess the current performance and processes. This will allow the Operational Certainty consultants to understand which subject matter experts to involve in further discussions and what methodology to apply. Following this, we would recommend a facilitated workshop to identify the challenges faced and agree potential improvement projects. Once the potential improvement projects are identified these will need to be refined into projects with a known scope and objective which can be executed. Emerson recommends that this stage be also completed as a traditional consultancy study.

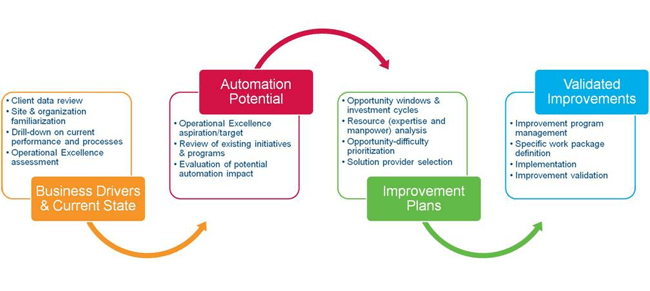

Whether you choose a formal consulting study, a collaborative workshop or a blend of the two, we will always follow the same basic methodology. This process and the different objectives are illustrated in the figure below. Each box represents a stage in the Operational Certainty journey and the arrows represent the engagements required to transition between the stages.

In practice, every engagement that we do is unique – we use our extensive toolbox to create a customised engagement model specifically designed to fit your needs, requirements and organisational culture. The important point to note is that there is not one methodology which meets all of our customer needs. Therefore, we recommend that you talk to an Emerson consultant so that they can apply the Operational Certainty framework to your particular situation resulting in a methodology which is optimised to you and will help your business achieve top quartile performance.

What can I expect to happen in an Operational Certainty Engagement?

Let’s assume that you will be completing all three stages of the operational excellence journey to arrive at an agreed automation delivery plan. The first stage will involve an Operational Certainty consultant visiting your site to talk to you and to understand how you operate your plants. This would typically involve a review of your operating data to assess how well you are performing in each of the domains. Your consultant may benchmark you against your industry or review your site operating KPI’s against your business objectives to understand the gap to help you address.

Once this exercise is complete the consultant will review your organization charts, perform a site walkthrough to aid familiarization and review any existing initiatives in progress. When understanding of the current business state has been achieved, your consultant will probably begin a series of structured interviews to further evaluate the challenges and issues present, or alternatively may defer this until the workshop. The final activity of the initial stage will be to complete an Operational Certainty Maturity model to document the divide between the current operating conditions and top quartile performance in each domain.

The information gathered during the initial stage will be used to define the remaining Operational Certainty methodology typically including a facilitated workshop. The facilitated workshop takes place at a convenient offsite location and is attended by both customer and Emerson representatives. The customer representatives are typically domain leaders and the Emerson representatives are typically subject matter experts and industry specific consultants.

The workshop process will be used to define the business challenges and the impact that automation can have on the challenges. Through a process of advanced ideation techniques, a number of automation themes (clusters of challenges) will emerge which are unique to the site or business. The attendees will then complete a number of exercises to define potential improvement projects which can address the automation themes.

These potential projects will be assessed using different tools, such as opportunity-difficulty prioritization, stakeholder mapping and force field analysis for barrier resolution. The potential improvement projects which are most viable will form the basis for a site or company automation strategy. Due to the limitations on time, these potential improvement projects will require further refinement in the final Operational Certainty consultancy stage.

A consultancy study is recommended to take the outcomes of the workshop and refine them into an automation strategy which has enough definition that it can be managed, implemented and finally validated. Your Operational Certainty consultant will work with you to fully define the automation strategy and any processes or procedures required to ensure its successful execution.

What will the outcomes of the Operational Certainty Engagement be?

The outcome of the Operational Certainty engagement will be an automation strategy aligned with your business needs. This automation plan will contain a number of improvement projects, supported by Emerson technologies and services where appropriate, which will make a real difference to improving how the plant is operated and maintained. Your assigned Emerson consultant will be able to support you with achieving operational excellence through execution of your automation strategy.

How long does it take?

The duration of the engagements is dependent upon the current status of the business, the number and complexity of the plants and potential for improvement. Generally speaking, you can expect the initial engagement to take a few weeks to a month. Preparation for the workshop will take approximately three months (mainly to ensure that the key people are available) and the actual workshop will take around a week to set up and run. The refinement of the workshop outcomes into an automation strategy can also take up to one month to complete. You can therefore expect to the overall engagement to take between three and six months to complete.

How do I arrange an Operational Certainty Engagement?

To arrange an Operational Certainty Engagement, please contact us. One of the Operational Certainty Consultants will contact you to understand how we can help.